MDF (Medium Density Fiberboard) is an engineered wood product made from wood fibers, wax, and resin, which are compressed and heated to form a dense, smooth board. It typically has a consistent structure throughout its thickness, but when you mention “MDF bears layers,” you might be referring to the layered structure or the way the material is constructed and its surface layers.

Here’s an explanation of how MDF is structured and why its layers matter:

Layered Construction of MDF:

- Composition:

- Wood Fibers: The primary material in MDF is wood fibers, which are often sourced from softwood or hardwood trees, or sometimes recycled wood products. These fibers are combined with resin and wax to form a thick, slurry-like mixture.

- Pressing Process: This mixture is then pressed at high temperatures to create a dense, uniform board. During the pressing process, the fibers bond together, forming a solid mass.

- Homogeneous Structure: Unlike plywood, MDF is not made of distinct layers of wood veneer. It’s a homogeneous board with a uniform composition throughout. This means it doesn’t have the visible “layers” like plywood does, but it may have subtle variations in density from one side to another due to the manufacturing process.

- Surface Layers of MDF:

- While MDF doesn’t have distinct layers like plywood, surface finishing plays an important role in its final appearance and durability.

- The outer surface of MDF can be smooth and is often sanded to perfection. This makes it suitable for painting, veneering, or coating.

- The inner structure (or core) is made up of the same fiberboard material, but it may be slightly less smooth and more porous compared to the surface layers. However, this difference is usually minimal.

- Types of MDF:

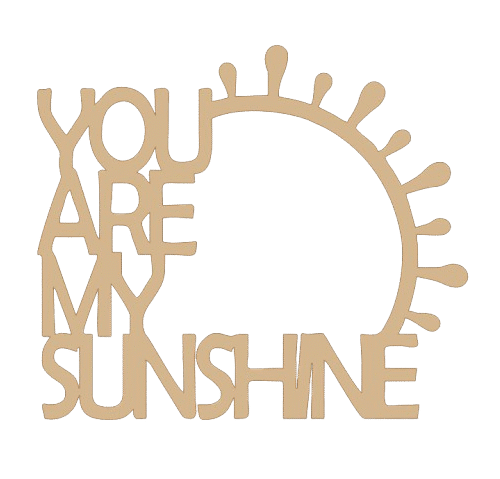

- Standard MDF: The most common type, used for a variety of applications like furniture, cabinetry, and decorative items (including coasters).

- Moisture-Resistant MDF: This type of MDF has been treated with additives to make it more resistant to water and humidity. It’s typically used in areas with higher moisture exposure, like kitchens or bathrooms.

- Fire-Retardant MDF: Some MDF boards are treated with fire-retardant chemicals for added safety, particularly in commercial or industrial environments.

- High-Density MDF (HDF): This is a denser version of MDF, used for high-end applications like flooring, or for projects that need more strength.

- Edge Treatment:

- Sealed Edges: Because MDF is porous, its edges are often sealed with a layer of resin or primer to prevent moisture from penetrating and causing the board to swell or degrade.

- Laminated or Veneered MDF: In some cases, MDF is covered with a veneer or laminate, which could give it a wood-like appearance or provide additional durability.

- Advantages of MDF’s Structure:

- Consistency: MDF’s dense, consistent structure makes it an ideal material for precision cutting, engraving, and painting. There are no knots, grain variations, or natural defects like in solid wood.

- Smooth Finish: Its smooth surface makes it perfect for high-quality finishes, which is why it’s commonly used for custom printing (such as sublimation) or other decorative purposes.

- No Visible Grain: MDF doesn’t have the visible grain patterns found in natural wood, which can be both an advantage (for uniform surfaces) or a drawback (if you’re looking for a natural wood look).

“Bears Layers” Meaning:

If you’re referring to “bearing layers” or “layered” MDF in a more metaphorical sense, this could refer to the ability of MDF to support a wide variety of surface treatments and finishes, such as:

- Layered coatings: Paint or laminate coatings applied to the surface.

- Layered textures: Sometimes, MDF can be used to create textured effects or layered designs (especially in woodworking or crafting), but these would be added on top of the basic MDF structure.

MDF and “Bear” Layers:

If you’re asking whether MDF can be used in a project involving layered or stacked structures (for instance, for making 3D art or multi-layer designs), the answer is yes—MDF can handle the creation of such layered effects very well. It’s commonly used in:

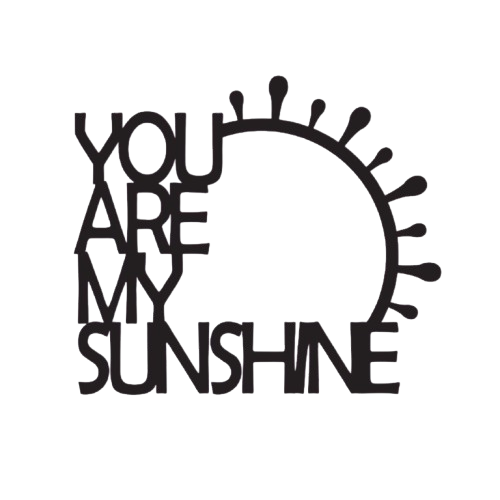

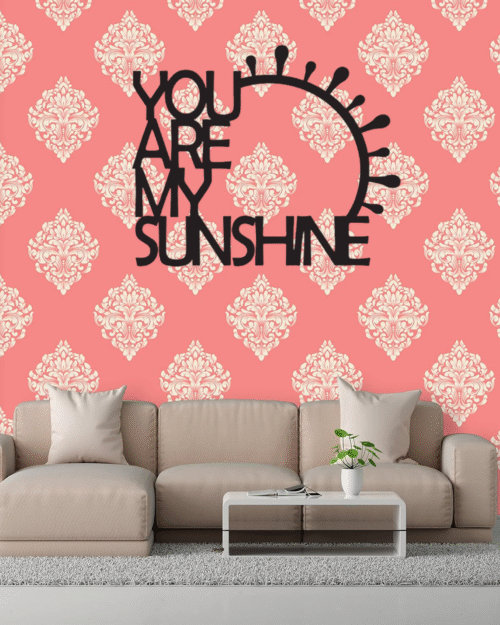

- Layered wall art: Artists often use MDF to create layered designs, where each layer is cut or engraved separately and stacked together for a 3D effect.

- Furniture Design: Some modern furniture designs stack MDF boards in layers to create a distinct look or enhance structural integrity.

Conclusion:

While MDF does not have physical layers like plywood (which is made of thin layers of veneer glued together), the term “MDF bears layers” may refer to the material’s ability to support various types of surface treatments or to be used in designs that incorporate multiple layers, such as in layered artwork or 3D projects. The smoothness and consistency of MDF make it an excellent material for these kinds of creative projects.

Reviews

There are no reviews yet.